The popularity of spray foam insulation has steadily increased in recent years. Although it can cost approximately two to three times more than traditional batts or blown/loose-fill insulation, the long-term benefits of spray foam gone bad often increase your cost. For those who have had negative experiences with the spray foam gone bad product, they would never recommend spray foam to anyone!

When installed correctly, spray foam acts as an insulator and an air barrier. Depending on the foam type, it can dampen sound and keep moisture out while reinforcing a structure. There are can be huge mistakes to using foam; there is a lot more to it than just aiming and pulling a trigger. Accurate chemical mixing and proper installation are critical. If either is done incorrectly, several problems can occur.

Potential issues with air flow

For example, when encapsulating an attic by foaming along roof rafters and decking, the entire attic must be sealed to bring the attic inside the thermal boundary. This means that all venting (soffit, ridge, gable or any other venting) must be removed or completely covered. This effect reduces air flow in and out of the attic space to make it “unvented” or “encapsulated.”

Foam reduces airflow in a home, so sometimes fresh air intakes need to be added. An industry standard test called a “Blower Door Test” is the best way to ensure that airflow falls within a target range for the home. If a foamed house is drafty or if the encapsulated attic feels more like the outside temperature, this indicates that exterior air has not been sealed out and is entering through gaps. When an attic is properly sealed and is part of the conditioned space, it should feel about as comfortable as any interior room in the home.

Potential issues with chemical mixing

If the spray foam gone bad chemicals are not mixed within the specified temperature range or correct ratio, problems can arise. The product may not adhere to roof decking, attic floors, wall cavities, etc., and/or not expand properly to fill all gaps and cavity surfaces. Improperly mixed applications can also off-gas indefinitely and produce oily residues.

spray foam gone bad

Potential issues with consistent thickness

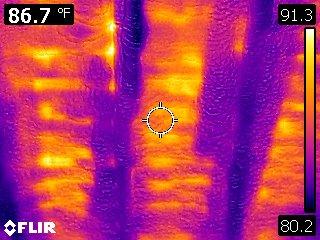

For spray foam insulation to be effective and maintain a consistent R-Value (resistance to heat), it must be applied in an even thickness. When it is not even, conduction can occur, thus rendering the spray foam gone bad ineffective. Using an infrared camera helps identify areas of uneven thickness. Or, one can use a marked stick or skewer to spot check various areas for consistency.

Potential issues with a single thermal boundary

For an attic or crawlspace/basement encapsulation, existing insulation (on the attic floor or crawlspace subflooring) must be extracted so as not to create two thermal boundaries. In such cases, double insulation is not better; spray foam gone bad can potentially cause moisture problems.

In conclusion, spray foam insulation – when mixed and applied correctly and evenly – can make a world of a difference in terms of insulating and air sealing a home. Conversely, when it is not done properly by trained professionals, spray foam gone bad can cause big problems. If you find yourself wondering why your spray foam gone bad insulated home is not as comfortable as you had anticipated or your bills seem to be high despite this energy efficient product, you may have a problem. Also, if the spray foam gone bad continues to off-gas and produces a smell or an oily residue or seems very uneven, something is not right. Contact a certified and reputable company to examine your home to identify and remedy the issue – either through additional foam or through re-venting and traditional weatherization techniques.

For all your insulation needs call Aladdin Insulation 678-528-7115